Umshini Wokuqoqa Kabusha Kabusha wePlastiki uhlobo lwempahla esetshenziselwa ukucubungula udoti noma ukulahlwa kwepulasitiki ibe yizinhlayiyana zepulasitiki ezisebenziseka kabusha. Incibilikisa phansi izinto zepulasitiki ezisetshenzisiwe njenge-PE, PP, noma i-PET futhi izenze kabusha zibe amapellets amancane, afanayo ngokusebenzisa i-extrusion nokusika.

Lo mshini udlala indima ebalulekile ekugayweni kabusha kwepulasitiki ngokuphendula amapulasitiki alahliwe abe izinto ezingavuthiwe zemikhiqizo emisha. Isiza ukunciphisa ukungcoliswa kwepulasitiki, yehlisa izindleko zokukhiqiza, futhi isekela ukukhiqizwa okusimeme kuzo zonke izimboni ezifana nokupakisha, ukwakha, nezimpahla zabathengi.

Ukuqonda izici, okuhle nobubi, kanye nokusetshenziswa okungenzeka koMshini Wokugaya Kabusha Wepulasitiki kuzokusiza wenze izinqumo ezingcono futhi ukhethe i-granulator efanele noma inhlanganisela ukuze uhlangabezane nezidingo zakho zokukhiqiza.

Qhubeka ufunda njengoba sinikeza imininingwane eminingi ngeMishini Yokugaywa Kabusha Yepulasitiki Yepulasitiki futhi sinikeza umhlahlandlela omfushane ekugcineni kwesihloko ukuze ukhethe i-granulator engcono kakhulu yephrojekthi yakho.

Izinhlobo zeUmshini Wokugaywa Kabusha Wepulasitiki

Imishini Yesimanje Yokugaywa Kabusha Kabusha Yepulasitiki iklanywe ngamasistimu awonga amandla, ukulawula izinga lokushisa okuzenzakalelayo, nokuhlunga okuthuthukisiwe ukuze kuqinisekiswe ama-granules ekhwalithi ephezulu. Zisetshenziswa kakhulu ekugayweni kabusha kwezitshalo, izimboni zemikhiqizo yepulasitiki, kanye nezikhungo zokucubungula imvelo ukuphatha imfucuza eminingi yepulasitiki, kusukela kufilimu namabhodlela kuya ezingxenyeni ezibunjwe ngomjovo.

Okulandelayo, sizoxoxa kafushane ngezinhlobo eziyi-12 ezihlukene zama-granulator.

1. Ukugaywa kabusha komugqa we-compactor granulation

I-Recycling Compactor Granulation Line iwuhlelo oluphelele olusetshenziselwa ukucubungula imfucumfucu yepulasitiki engasindi—njengamafilimu, izikhwama ezilukiweyo, nezinto ezinegwebu—kuzifake kumapulastiki aminyene. Ihlanganisa ukuhlanganisa, ukukhishwa, ukuhlunga, kanye ne-pelletizing ibe yinqubo eyodwa eqhubekayo. I-compactor icindezela kuqala izinto ezithambile noma ezinkulu, ikwenze kube lula ukuzondla ku-extruder ngaphandle kokuvala ibhuloho noma ukuvala.

Izinzuzo

Ukondla Okuphumelelayo: I-compactor eyakhelwe ngaphakathi icubungula izinto ezilula nezithambile, ivimbela ukuvinjwa kokudla.

Isistimu Edidiyelwe: Ihlanganisa ukuminyanisa, i-extrusion, ukuhlunga, kanye ne-pelletizing emgqeni owodwa oqhubekayo.

Ukonga Isikhala Nomsebenzi: Idizayini ehlangene ene-automation ephezulu inciphisa isidingo somsebenzi wezandla nendawo yefekthri.

I-Wide Material Compatibility: Iphatha amapulasitiki athambile ahlukahlukene njengefilimu ye-PE/PP, izikhwama ezilukiweyo, nezinto zegwebu.

Ikhwalithi Ye-Pellet Engaguquki: Ikhiqiza izingcwecwe zepulasitiki ezifanayo ezifanele ukusetshenziswa kabusha ekukhiqizeni.

Ukubi

Ayifanele Ipulasitiki Eqinile: Amapulasitiki aqinile noma aqinile (isb., izingxenye ezibunjwe ngomjovo, amabhodlela) angase adinge eminye imishini.

Kudingeka Ukuhlanzeka Kwezinto Ezibalulekile: Umswakama ophezulu noma amazinga okungcola (njengokungcola noma iphepha) angaphazamisa ukusebenza kanye nekhwalithi ye-pellet.

Ukugcinwa Okujwayelekile Kudingeka: Izindawo ezisebenza ngaphansi kwe-compactor kanye nezihlungi zidinga ukuhlanzwa ngezikhathi ezithile ukuze kuqinisekiswe ukusebenza okuzinzile.

Izinhlelo zokusebenza

I-Agricultural Film Recycling: Yefilimu ye-PE mulch, ifilimu ye-greenhouse, kanye namanye amapulasitiki emfucuza yasepulazini.

I-Post-Consumer Plastic Packaging: Ilungele ukucubungula izikhwama zokuthenga, ifilimu elula, izikhwama zeposi, njll.

Ukubuyiselwa Kwezicucu Zezimboni: Isebenzisa kabusha imfucuza yokukhiqiza evela kubakhiqizi befilimu nabalukiweyo bezikhwama.

Izimboni Zokugaywa kabusha kwePlastiki: Zifaneleka kakhulu ezindaweni eziphethe umthamo omkhulu wemfucuza yepulasitiki ethambile.

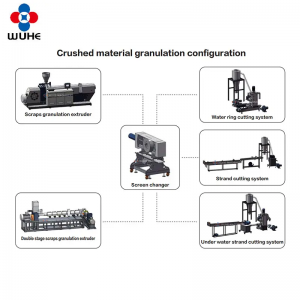

2.Umugqa we-granulation wento echotshoziwe

I-Crushed Material Granulation Line iyisistimu yokugaywa kabusha kwepulasitiki eklanyelwe ukucubungula udoti wepulasitiki oqinile osevele uhlihliziwe noma ochotshoziwe waba ama-flakes. Lokhu kufaka phakathi izinto ezifana ne-HDPE, PP, PET, ABS, noma i-PC evela emabhodleleni, iziqukathi, nezinsalela zezimboni. Ulayini ngokuvamile uhlanganisa isistimu yokuphakelayo, i-extruder eyodwa noma i-twin-screw, iyunithi yokuhlunga, isistimu ye-pelletizing, nesigaba sokupholisa/sokomisa.

Izinzuzo

Ukuphakelwa Okuqondile Kwezinto Ezichotshoziwe: Asikho isidingo sokuminyanisa kwangaphambili; ifanele amapulasitiki aqinile njengamabhodlela, iziqukathi, nezingxenye zomjovo.

Okukhiphayo Okuzinzile: Isebenza kahle ngeyunifomu, izinto eziminyene, ihlinzeka ngekhwalithi engashintshi kanye nekhwalithi ye-pellet.

Ukusebenza Okuphezulu: Idizayini eqinile yesikulufu kanye nesistimu yokususa umoya esebenzayo ithuthukisa ukuncibilika futhi inciphise izinkinga zomswakama.

Ukucushwa Okuguquguqukayo: Kungahlonywa ngezikhipheli zesiteji esisodwa noma ezimbili, indandatho yamanzi noma ama-pellets asekelwe ohlotsheni lwempahla.

Ilungele Ukugaywa kabusha Okuhlanzekile: Isebenza kahle kakhulu lapho ucubungula ama-flakes epulasitiki ahlanzekile, ahlungiwe emigqeni yokuwasha.

Ukubi

Ayilungele Ipulasitiki Ethambile noma Ethambile: Izinto ezilula ezifana namafilimu noma amagwebu zingadala ukuntengantenga kokudla noma ukuvala ibhuloho.

Idinga ukugezwa ngaphambilini: Izinto ezingcolile noma ezingcolile ezichotshoziwe zidinga ukuhlanzwa kahle ngaphambi kokugcwaliswa.

Okungafaneleki Kancane Kwepulasitiki Exubile: Ukuvumelana kwezinto ezibonakalayo kuthinta ikhwalithi ye-pellet; izinhlobo ze-polymer ezixubile zingadinga ukuxutshwa noma ukuhlukaniswa.

Izinhlelo zokusebenza

I-Rigid Plastic Recycling: Okwamabhodlela e-HDPE/PP, iziqukathi ze-shampoo, imiphongolo yokuhlanza, njll.

I-Post-Industrial Plastic Scrap: Ifanele izinsalela ezichotshoziwe ezivela ekubunjweni komjovo, ukukhishwa, noma ukubunjwa kokushaywa.

Ama-Flakes Awashiwe Asuka Kulayini Wokugaya Kabusha: Isebenza kahle ngama-PET ahlanzekile, ama-PE, noma ama-PP flakes asuka ezinhlelweni zokugeza amabhodlela.

Abakhiqizi be-Plastiki Pellet: Ilungele abakhiqizi abaguqula i-regrind ehlanzekile ibe ama-pellets asebenzisekayo ukuze ajovwe noma akhishwe.

3. Umugqa we-pelletizing wesikhwama esilukiweyo

I-Woven Fabric Bag Recycling Pelletizing Line iwuhlelo olukhethekile lokugaywa kabusha oluklanyelwe ukucubungula izikhwama ezilukiwe ze-PP (i-polypropylene), i-raffia, izikhwama ze-jumbo (ama-FIBC), nezinye izindwangu zepulasitiki ezifanayo. Lezi zinto ngokuvamile azisindi, azikwazi ukukhala, futhi kunzima ukuzondla ngokuqondile kumasistimu e-pelletizing omdabu ngenxa yesakhiwo sawo esikhulu. Lo mugqa uhlanganisa ukuchotshozwa, ukuhlanganisa, ukukhishwa, ukuhlunga, kanye ne-pelletizing ibe yinqubo eqhubekayo eguqula izinto zepulasitiki ezilukiwe ezisetshenzisiwe zibe ama-pellets epulasitiki afanayo.

Lesi sixazululo silungele ukugaywa kabusha kwemfucumfucu yokupakisha eyakhiwe ngemuva kwezimboni kanye nangemuva komthengi, kusize ukunciphisa ukungcoliswa kwemvelo kanye nokuvuselela izinto zokusetshenziswa embonini yepulasitiki.

Izinzuzo

I-Integrated Compactor System: Icindezela ngokuphumelelayo izinto ezingasindi, ezilukiweyo ukuze kuqinisekiswe ukudla okubushelelezi nokuzinzile ku-extruder.

Ukusebenza Okuphezulu: Idizayinelwe ukucutshungulwa kwamandla aphezulu ngokusebenza okuqhubekayo kanye nezidingo zabasebenzi abaphansi.

Okukhiphayo Okuhlala isikhathi eside futhi Okuzinzile: Ikhiqiza ama-pellets afanayo anezici ezinhle zokukhanda, ezilungele ukusetshenziswa futhi ezansi nomfula.

Iphatha Izinto Eziyinselele: Yakhelwe ngokukhethekile ukuphatha izikhwama ezilukiweyo, izikhwama ze-jumbo ezinamalayini, kanye nemfucuza ye-raffia.

Idizayini Engenziwa Ngokwezifiso: Ilungiseka ngezinhlelo ezihlukahlukene zokusika, zokususa umoya, kanye nezihlungi eziklanyelwe izimo zempahla ehlukene.

Ukubi

Ukwelashwa Kwangaphambili Kudingeka Kaningi: Izikhwama ezilukiwe ezingcolile zingase zidinge ukuwashwa nokomiswa ngaphambi kokugaywa kabusha ukuze kugcinwe ikhwalithi ye-pellet.

Ukusetshenziswa Kwamandla Okuphezulu: Ngenxa yokuhlangana nokuncibilika kwezinto eziminyene, uhlelo lungasebenzisa amandla engeziwe.

Ukuzwela Kwezinto Ezibalulekile: Ukujiya kwempahla okungahambisani noma imicu yokuthunga esele kungase kuthinte ukuphakela nokuzinza kwe-extrusion.

Izinhlelo zokusebenza

Ukugaywa kabusha kwamasaka e-PP: Alungele izikhwama zikasimende, amasaka elayisi, izikhwama zikashukela, nezikhwama zokudla kwezilwane.

I-Jumbo Bag (FIBC) Ukucutshungulwa kabusha: Isixazululo esisebenzayo sokugaywa kabusha kweziqukathi zenqwaba eziguquguqukayo eziphakathi nendawo.

I-Textile and Raffia Waste Recycling: Ifanele abakhiqizi bezindwangu ezilukiweyo kanye nemikhiqizo ye-raffia ukuze baphinde basebenzise ukunqunywa konqenqema kanye nezilahlwa.

Ukukhiqizwa Kwe-Pellet Yepulasitiki: Ikhiqiza izingcezu ze-PP zekhwalithi ephezulu ukuze ziphinde zisetshenziswe ekubumbeni umjovo, ukukhishwa, noma ukufutha kwefilimu.

4.EPS/XPS Granulation Line

I-EPS/XPS Granulation Line iwuhlelo olukhethekile lokugaywa kabusha oluklanyelwe ukucubungula i-polystyrene enwetshiwe (EPS) kanye nemfucumfucu yegwebu le-polystyrene (XPS) ekhishiwe ibe yizinhlayiyana zepulasitiki ezisebenziseka kabusha. I-EPS ne-XPS izinto ezingasindi, ezinegwebu ezivame ukusetshenziswa ekufakweni, ekufakeni, nasekwakheni. Ngenxa yobukhulu bazo kanye nokuminyana okuphansi, kunzima ukuzisebenzisa zisebenzisa izinto ezijwayelekile zokugaywa kabusha kwepulasitiki. Lo mugqa we-granulation ngokuvamile uhlanganisa ukuchotshozwa, ukuhlanganisa (ukuncibilika noma ukuminyana), ukukhishwa, ukuhluza, namasistimu okugaya.

Inhloso eyinhloko yalo mugqa ukunciphisa umthamo, ukuncibilika, nokucubungula kabusha imfucumfucu ye-EPS/XPS ye-foam ibe amapellets e-polystyrene afanayo (GPPS noma ama-HIPS), angasetshenziswa futhi ekukhiqizeni ipulasitiki.

Izinzuzo

Ukuncishiswa Kwevolumu: I-compactor noma isistimu ye-densifier inciphisa kakhulu umthamo wezinto zegwebu, ithuthukise ukusebenza kahle kokuphakelayo.

Ukukhipha Okuphezulu Okubalulekile Okukhanyayo: Iklanyelwe ngokukhethekile igwebu eliminyana kancane, iqinisekisa ukudla okuzinzile kanye nokukhishwa okuqhubekayo.

Idizayini Yesikulufu Eyonga Amandla: Isikulufu esithuthukisiwe nesakhiwo somphongolo siqinisekisa ukuncibilika okusebenzayo ngokuncishiswa kokusetshenziswa kwamandla.

Ivumelana Nemvelo: Isiza ekunciphiseni imfucumfucu yokulahla imfucumfucu futhi isekela ukusetshenziswa okuyindilinga kokupakishwa kwegwebu nezinto zokuvikela.

Okukhipha Kabusha Kabusha: Ama-granules akhiqiziwe afanele ukusetshenziswa futhi ezinhlelweni ezingezona ezokudla njengamashidi okufakwa ngaphakathi noma amaphrofayili epulasitiki.

Ukubi

Idinga Igwebu Elihlanzekile Nelomile: I-EPS/XPS kumele ingabi namafutha, ukudla, noma ukungcoliswa kanzima ukuze kugcinwe ikhwalithi ye-pellet.

Kudingeka Ukulawula Iphunga Nokushisa: Igwebu elincibilikayo lingase likhiphe intuthu; umoya ofanele noma izinhlelo zokukhipha umoya zibalulekile.

Ayifanele i-Mixed Plastics: Uhlelo lwenzelwe i-EPS/XPS ehlanzekile; izinto ezixubile zingase zivale noma zehlise ikhwalithi yokuphuma.

Izinhlelo zokusebenza

I-Packaging Foam Recycling: Ilungele ukugaywa kabusha kwephakheji ye-EPS emhlophe esetshenziswa ezintweni zikagesi, izinto zikagesi, nefenisha.

Ukubuyiswa Kwempahla Yokwakha: Ifanele izinsalela zebhodi le-XPS ezivela ku-insulation yesakhiwo namaphaneli odonga.

I-Foam Factory Waste Management: Isetshenziswa abakhiqizi bomkhiqizo we-EPS/XPS ukuvuselela unqenqema lokukhiqiza kanye nezingcezu ezinqatshiwe.

I-Polystyrene Pellet Production: Iguqula imfucumfucu yegwebu ibe yizinhlayiyana ze-GPPS/HIPS zezinhlelo zokusebenza ezansi nomfula njengamashidi epulasitiki, iziphanyeko, noma imikhiqizo ebunjiwe.

5. I-Parallel Twin Screw Granulation Line

I-Parallel Twin Screw Granulation Line iyisistimu yokucubungula yepulasitiki esebenzisa izikulufu ezimbili ezihambisanayo zokuncibilika ukuze zincibilike, zixube, futhi zenze i-pelletize izinto ezihlukahlukene zepulasitiki. Uma kuqhathaniswa nama-extruder angama-screw single, izikulufu ezingamawele zihlinzeka ngokuxubana okungcono, okuphumayo okuphezulu, nokulawula okukhulu kuzimo zokucubungula. Lolu hlelo lufaneleka ngokukhethekile ukugaywa kabusha kwamapulasitiki axubile, izithasiselo ezihlanganisiwe, kanye nokukhiqiza ama-granules epulasitiki ekhwalithi ephezulu anezici ezithuthukisiwe.

Ulayini ngokuvamile uqukethe isistimu yokuphakelayo, i-parallel twin screw extruder, iyunithi yokuhlunga, i-pelletizer, nesigaba sokupholisa/sokomisa, esidizayinelwe ukusebenza okuqhubekayo nokuzinzile.

Izinzuzo

Ukuxuba Okuphezulu Nokuhlanganiswa: Izikulufu ezimbili zinikeza i-homogenization enhle kakhulu, evumela ukuhlanganiswa kwama-polymer ahlukene kanye nezithasiselo.

Ukusebenza Okuphezulu Nokusebenza Kahle: Ihlinzeka ngokukhiphayo okuphezulu nokuzinza okungcono kokucubungula uma kuqhathaniswa nama-extruder angama-screw single.

Ukuphathwa Kwezinto Ezihlukahlukene: Ilungele ukucubungula amapulasitiki anhlobonhlobo, afaka i-PVC, i-PE, i-PP, i-ABS, namapulasitiki axutshwe kabusha agaywe kabusha.

Ukulawulwa Kwenqubo Okuthuthukisiwe: Isivinini esizimele sesikulufu nezindawo zokushisa kuvumela ukulungiswa okunembile kwekhwalithi ye-pellet ephelele.

I-Degassing Ethuthukisiwe: Ukususwa okusebenzayo komswakama kanye nokuguquguquka, okuholela kumapellets ahlanzekile.

Ukubi

Utshalomali Olukhulu Lokuqala: Amasistimu wezikulufi zamawele ngokuvamile abiza kakhulu ukuwathenga nokuyigcina kunesikulufu esisodwa.

Ukusebenza Okuyinkimbinkimbi Nokunakekelwa: Kudinga ama-opharetha anamakhono nokunakekelwa okuvamile ukuze kugcinwe izikulufu nemiphongolo isesimweni esihle.

Ayilungele Izinto Ezibonakalayo Eziphakeme Kakhulu: Ezinye izinto ezibonakalayo ezibonakalayo zingadinga okokusebenza okukhethekile noma izimo zokucubungula.

Izinhlelo zokusebenza

Ukwenziwa kabusha kwePlastiki: Kusebenza kahle ekucubunguleni kabusha udoti wepulasitiki oxubile ube yizinhlamvana ezifanayo ukuze ziphinde zisetshenziswe.

I-Compounding and Masterbatch Production: Isetshenziswa kakhulu ekukhiqizeni izinhlanganisela zepulasitiki ezinama-filler, ama-colorants, noma izithasiselo.

I-PVC ne-Engineering Plastics Processing: Ilungele ukuphatha ama-polymer azwela ukushisa futhi ayinkimbinkimbi.

Ukwenziwa Kwezinto Ezisebenza Kakhulu: Kusetshenziswa ekukhiqizeni amapulasitiki akhethekile anezakhiwo ezifanelana nemishini noma zamakhemikhali.

Amaphuzu Abalulekile Wokukhetha Okungcono Kakhulu Uhlobo Lomshini Wokugaywa Kabusha Wepulasitiki

Okulandelayo ukucatshangelwa okubalulekile kokukhetha koMshini Wokugaywa Kabusha Kwepulasitiki ongagcwalisa izidingo zakho zokukhiqiza.

1. Yazi Uhlobo Lwakho Lwempahla

Ipulasitiki Ethambile (isb., ifilimu, izikhwama, igwebu): Khetha umshini onekhompiyutha noma i-densifier ukuze uqinisekise ukudla okubushelelezi.

Ipulasitiki Eqinile (isb., amabhodlela, iziqukathi eziqinile): Ulayini we-granulation wempahla echotshoziwe onokuphakelwa okuzinzile ufaneleka kakhulu.

Amapulasitiki Axubile noma Angcolisiwe: Cabangela ama-extruder angamawele ngezikulufu ezinamandla okuxubana namandla okuhlunga.

2. Hlola Izidingo Zekhono Lokukhipha

Linganisela ivolumu yakho yansuku zonke noma yanyanga zonke yokucubungula.

Khetha imodeli ehambisana nomthamo owufunayo (kg/h noma amathani/ngosuku) ukuze ugweme usayizi ongaphansi noma oweqile.

Ukuze kusetshenziswe kabusha ngezinga elikhulu, amasistimu we-twin-screw aphezulu noma ama-double stage alungile.

3. Hlola Izidingo Zokuphakela Nezokwelashwa Ngaphambili

Ingabe impahla yakho idinga ukuwashwa, ukomiswa, noma ukuchotshozwa ngaphambi kokuba kugaywe?

Eminye imishini ihlanganisa ama-shredders ahlanganisiwe, ama-washer, noma ama-compactor. Ezinye zidinga okokusebenza kwangaphandle.

Izinto ezingcolile noma ezimanzi zidinga amasistimu we-degas aqinile kanye nokuhlunga okuncibilikayo.

4. Cabangela Ikhwalithi Yokugcina Yepellet

Okokusebenza okusezingeni eliphezulu (isb. ukufutha kwefilimu, ukubumba umjovo), usayizi we-pellet ongaguquki kanye nodaba oluhlanzekile.

Imishini enokulawula okunembile kwezinga lokushisa kanye nezishintshi zesikrini ezizenzakalelayo zikhiqiza ama-granules ahlanzekile, afanayo.

5. Ukuphumelela Kwamandla & Okuzenzakalelayo

Bheka imishini enamamotho alawulwa yi-inverter, izifudumezi ezonga amandla, ne-automation ye-PLC.

Amasistimu azenzakalelayo anciphisa izindleko zabasebenzi futhi aqinisekise ikhwalithi yokukhiqiza engaguquki.

6. Ukugcinwa Nokusekelwa Kwezingxenye Ezisele

Khetha umshini kumnikezeli onokwethenjelwa onesevisi ephendula ngokushesha, usekelo lobuchwepheshe, nezingxenye ezisele ezifinyeleleka kalula.

Imiklamo elula ingase yehlise isikhathi sokuphumula futhi yehlise izindleko zokulungisa zesikhathi eside.

7. Ukwenza ngokwezifiso nokwandiswa kwekusasa

Cabangela imishini enamadizayini we-modular avumela ukuthuthukiswa (isb, ukungeza i-extruder yesibili noma ukushintsha uhlobo lwe-pelletizing).

Isistimu eguquguqukayo ivumelana nezinhlobo zezinto ezintsha noma umkhiqizo ophezulu njengoba ibhizinisi lakho likhula.

Cabanga nge-WUHE MACHINERY's Plastic Recycling Kabusha Granulation Machine Service

Njengomkhiqizi ochwepheshe onokuhlangenwe nakho kweminyaka engaphezu kwengu-20, I-WUHE MACHINERY (Zhangjiagang Wuhe Machinery Co., Ltd.) iyahamba phambili ekwakhiweni, ekukhiqizeni, nasekusebenzeleni umhlaba wonke kwemishini yokugaywa kabusha kwepulasitiki.

Njengoba kunezinhlelo ezingaphezu kuka-500 ezifakiwe kanye namathani angaphezu kwezigidi ezingu-1 epulasitiki acutshungulwa minyaka yonke-ukunciphisa amathani alinganiselwa ku-360,000 okukhishwa kwe-CO₂-WUHE ibonise amandla ayo obuchwepheshe kanye nomthelela wemvelo.

Besekelwa izitifiketi ze-ISO 9001 nezitifiketi ze-CE, bahlinzeka ngezixazululo ezihlanganisiwe zefilimu, isikhwama esilukiweyo, i-EPS/XPS, ipulasitiki echotshoziwe, kanye nemigqa yokuhlanganisa isikulufu esikabili. Ukulawula kwabo ikhwalithi okuqinile, idizayini yesistimu eyimojula, ukuguquguquka kwe-OEM/ODM, nokwesekwa okuphendulayo ngemva kokuthengisa kuqinisekisa ukuthi abathengi be-B2B bathola izixazululo ezinokwethenjelwa, ezisebenza kahle kakhulu, nezilungiselelwe kabusha emhlabeni wonke.

Khetha I-WUHE MACHINERY ukuze uthole ukusebenza okuthembekile, izixazululo ezenziwe ngokwezifiso zokugaywa kabusha, kanye nozakwethu othembekile ekwakheni imboni yepulasitiki eluhlaza, esimeme kakhudlwana.

Isikhathi sokuthumela: Jul-01-2025