Ifilimu ye-PP/PE nezikhwama ezigaya kabusha ulayini we-compactor granulation

Ipharamitha eyinhloko

I-Conveyor+ umtshina wensimbi

● Ihambisana nekhompiyutha ukuze ukwazi ukulawula okuzenzakalelayo.

● Umtshina wensimbi uphakathi kwebhande, ukuze uthole insimbi ezintweni zokwakha, uhlobo lwe-China olwenziwe ngokwezifiso noma uhlobo lwesiJalimane.

Umshini wokuhlanganisa

● Lo mshini wamukela ubuchwepheshe obungenisiwe, usebenzisa ukugaya ngokushesha, ukuxuba okuqhubekayo, ukushisisa kokuxubana, ukupholisa ngokushesha kanye nomgomo wokufinyela, kubangele ifilimu yepulasitiki, ishidi, umugqa, ucingo, ishubhu lepulasitiki elithambile, izinto zegwebu, izinto eziwohlokayo kanye ne-granular kusuka kumfucumfucu kuya ekukhiqizeni kabusha, okuyimodeli yakamuva yepulasitiki yokuvuselela imishini efanelekile yokugawula.

Idivayisi yokuphakela ifilimu

● Uma ifilimu isesimweni sokugoqwa, le divayisi yokondla ingafakwa ukuze kuzuzwe umsebenzi wokuphakelwa kwefilimu ku-inthanethi, ukonga umsebenzi. Ngokwezifiso

Idivayisi yokuphakela eceleni

● Uma unezinto ezithile ezichotshoziwe ezidinga ukuxutshwa nezinto zefilimu ukuze zenze ama-pellets, singengeza idivayisi yokuphakelayo emzimbeni wombhobho ohlangene. Ngokwezifiso.

Umshini we-Extruder

● I-scruder yesikulufu esisodwa esikhipha umoya osebenzayo ukuze kuthuthukiswe ikhwalithi yezinto. Ifakwe umklamo okhethekile womgqomo nesikulufa kanye nesistimu yokukhipha isikulufa esisodwa, ingaqinisekisa isivuno esikhulu.

Vacuum air exhausting system

● Ukuqeda umoya okusebenzayo ukuze kuthuthukiswe ikhwalithi yezinto ezibonakalayo.

● Isitayela esikhathazayo: isihlungi samanzi evacuum.

● Igumbi le-vacuum: umklamo okhethekile.

● Ipuleti lekhava yevacuum: ingxubevange ye-aluminium.

● Vacuum tube: izinga lokushisa kanye nengcindezi ukumelana namashubhu erabha.

I-granulation yesiteji esisodwa kanye ne-double stage granulation kunqunywa ngokubalulekile. Ngezansi kunemininingwane eningiliziwe ye-extruder yesigaba sesibili.

I-extruder yengane

● I-extruder enezigaba ezimbili ingakhipha amanzi nokungcola ngokuphumelelayo ezintweni ezisetshenziswayo, futhi izinga lezinhlayiyana lingcono.

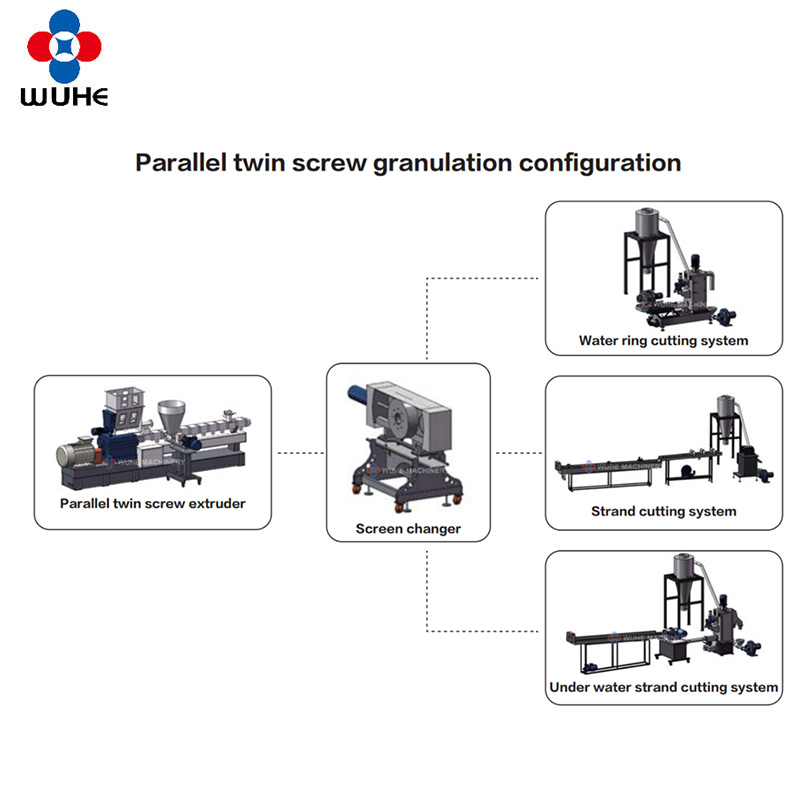

Ukushintsha isikrini

● Abashintshi besikrini abahlukene bahlangabezana nezidingo zamakhasimende ahlukene.

Ngokuyinhloko sinezinhlobo ezintathu zesistimu yokusika ama-pellets:

1. Uhlelo lokusika indandatho yamanzi.

2. Uhlelo lokusika i-strand.

3. Uhlelo lokusika imicu engaphansi kwamanzi.

Ngokusekelwe ezicini ezihlukahlukene zezinto ezibonakalayo, sizoncoma izindlela ezihlukene zokusika.

1. Uhlelo lokusika indandatho yamanzi

● Uhlelo lokusika lwamukela indandatho yamanzi ekhanda le-extrusion die ukusika, engaqinisekisa ukubukeka okuphelele kwezinhlayiya.

Umshini wokukhipha amanzi we-Centrifugal

● Lo mshini unezinzuzo eziningi, ezifana nezinga eliphezulu lokuphelelwa amanzi emzimbeni, ukusetshenziswa kwamandla okuphansi, ukusebenza kahle okuphezulu, izinga eliphezulu lokuzishintshashintsha, futhi kunciphisa kakhulu umfutho wabasebenzi. Ukuphelelwa amanzi emzimbeni kuhlanzekile, futhi kungageza nesihlabathi esincane nama-sundries amancane epulalini.

2. Strand cutting system

● Kwezinye izinto ezine-viscosity ephezulu, njenge-PP, sincoma ukusebenzisa indlela yokusika imicu.

3. Uhlelo lokusika lokuma ngaphansi kwamanzi

● Ifanele izinto ezincibilika kakhulu, njenge-PET ne-PP nokunye.

● Ukomiswa kwamapayipi omoya

Amanzi angaphezulu kwama-pellets ayahwamuka ngomgomo wokudlulisa umoya, futhi athuthe ama-pellets omisiwe endaweni yokuwaqoqa, bese eyokwelashwa okulandelekayo.

Uhlelo lokulawula ugesi

● Ukulawula okuzenzakalelayo kwe-PLC

Umdwebo wezinto ezibonakalayo